Eelarve 200 €, kahjuks peab nentima, et plaanid jäid plaanideks, 350€ on reaalsem number.

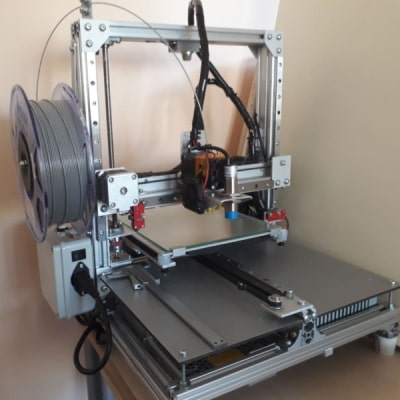

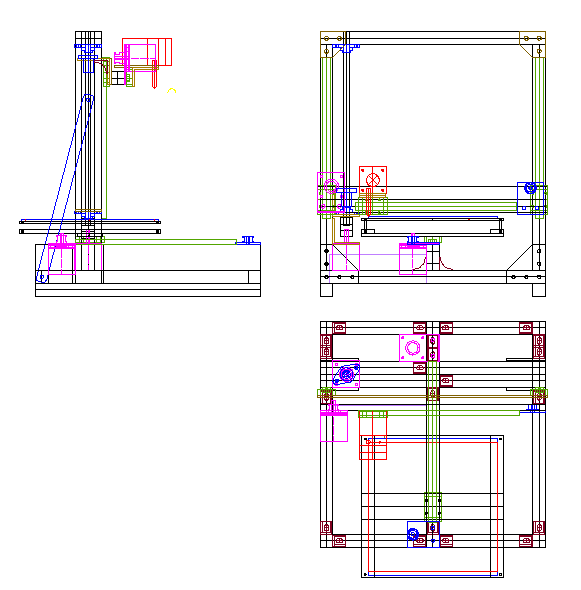

Lühidalt parameetrid / jupid:

Tööpinge 24V.

Gabariidid: 350x350x420 (X*Y*Z).

Prindiala 200 x 200 x 200 mm.

3 telge MGN12H lineaarjuhikutel,- laagritel.

X, Y telg ülekanne - GT2 6 mm hammasrihm (kumm)

Z telg kruviülekanne, 1 stepper, 2 kruviülekannet, sünkroniseeritud GT2 rihmaga ülaosas.

Toiteplokk 24V, võimsus 150W, 6.5A.

Alusplaat soojendusega MK3 220x220x3 12V 120W/ alusisolatsioon / trükipind borosilikaatklaas, MK3 hotbed termistor 100k

Prindipea MK8 "direct extruder" 1,75mm.

Prindipea stepper: Nema 17 42BY45040-24D I=1.5A

Extruder termistor: NTC 3950 100k

X, Y, Z Stepperid Nema 17 HS4401 I=1.68A.

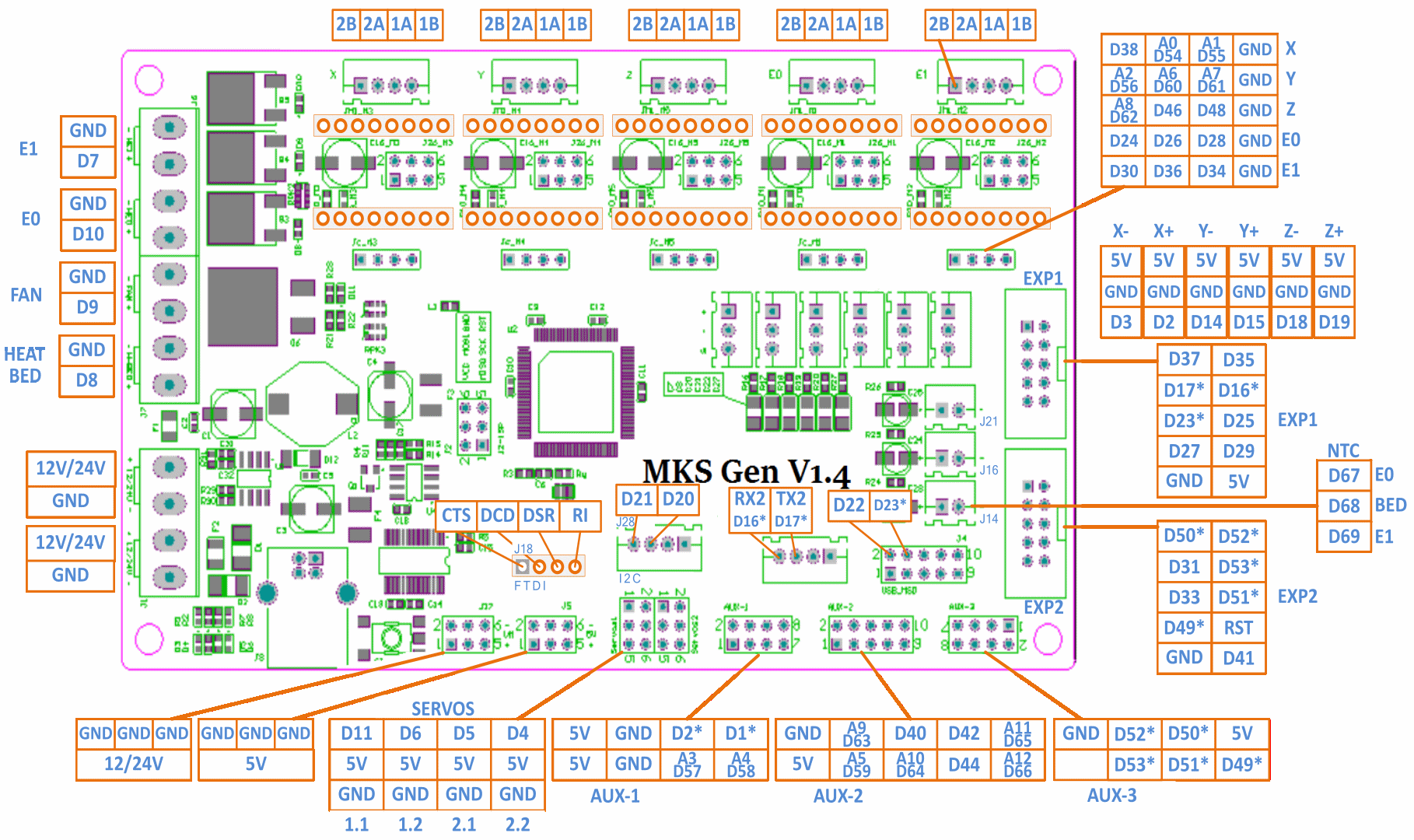

Juhtmoodul MKS GEN V1.4, driverid TMC2209 V.1.2, Raspberry Octoprint, Klipper.

Töölaua sensor LJ18A3-8-Z/BX-5V.

Konstruktsioon alumiiniumprofiilid 2020, 2040 + hulgaliselt kinnituselemente.

------------------------------------

Tarkvara seadistused.

* Autocad / Fusion 360 -> 3D.stl

* STL faili parandamine -> Meshmixer (https://www.meshmixer.com/download.html)

* Viilutamine (slicing) STL -> Gcode Cura.

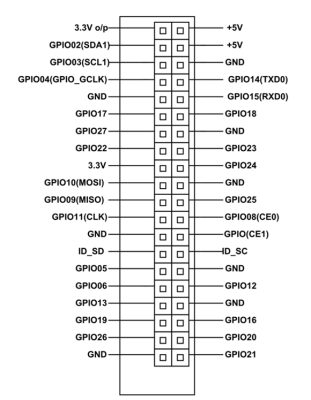

* Raspberry Pi 3

Pi 3 jahutus GPIO18 -> kontroll pin läbi transistori.

Seadistus: lisa faili /boot/config.txt rida: dtoverlay=gpio-fan,gpio_pin=18,temp=55000

Kui temp üle 55C - ON, langeb 10C (55-10=45C) - OFF

* Octoprint

Loe: https://www.raspberrypi.org/blog/how-to-set-up-octoprint-on-your-raspberry-pi/

Juhend on lihtne ja selge ning jätan installi kirjeldamise vahele (SD kaardile) - kõik töötab.

SSD on hea asendus SD'le. -> kirjuta image SSD-le ja lisa faili /boot/config.txt jupp: program_usb_boot_mode=1

* OctoKlipper pug-in, võimaldab conf. faili: printer.cfg mudida Octoprint GUI-s.

* Klipper https://www.klipper3d.org

Install https://www.klipper3d.org/Installation.html

(MKS GEN V1.4 (Atmega AVR, atmega2560, 16MHz)

* GCode https://marlinfw.org/docs/gcode/G002-G003.html

* MCU kasutusjuhend: https://www.roboter-bausatz.de/media/pdf/0b/f0/a7/MKS-Gen-DataSheet.pdf

MKS GEN V1.4 (Atmega AVR, atmega2560, 16MHz)

* Webcam Logitech C270 hakib // I fixed the problem by changing

Type=forking to Type=simple in/etc/systemd/system/webcamd.service and then running systemctl daemon-reload; systemctl stop webcamd; systemctl start webcamd.-----------------------------------------------------------------

* Driver seadistused:

Stepper Nema 17 HS4401, I= 1,68 A

Stepper Nema 17 42BY45040-24D, I = 1,5 A

** Driver TMC2209 loe: https://www.klipper3d.org/Config_Reference.html

https://mak3r.de/2020/04/03/stepper-driver-current-and-vref-calculator/

Max run_current 1.2 A !!

Klipper printer.cfg run_current: 0.95 (A)

** Driver DRV8825 seadistus:

Stepper Nema 17 HS4401, I= 1,68 A

VRF = (1,68/2) * 0,9 = 0,756 ~ 0,75 V

Stepper Nema 17 42BY45040-24D, I = 1,5 A

VRF = (1,5/2) * 0,9 = 0,675 ~ 0,67 V

* Klipper extras:

https://github.com/KevinOConnor/klipper/blob/9a92b346fd81386c54464b45d8310dab972b6bbd/config/example-extras.cfg#L1441

* Klipper macros: https://github.com/Desuuuu/klipper-macros

* Ühendus: https://github.com/KevinOConnor/klipper/issues/2828

* PID seadistust, Klipper, mackro

* Z-probe

LJ18A3-8-Z/BX-5V -> 5V ja 8mm reageerimise kaugus

* PETG cura settings vt. https://pupujuku.ddns.net/info/prindiklubi/petg-seadistus

* Detaili jahutus 2 ventilaatorit

4010 24V DC Fan 40x40x10mm Power consumption: 1.92W Current rating: 0.08A Noise: 24DBA

********************

Printeri turvalahendused

********************

=Octoprint plugin Temperature Failsafe=

Kui nozzle (280 C) või Bed (130 C) temp ületab etteantud max. väärtuse:

* Nozzle / Bed OFF

* Katkestatakse pintimine

* Käivitub PI shell script: "gpio -g write 12 1" GPIO12 -> HIGH (... arduiono sisend vt =AC 220V=...)

DIY optocoupler:

Raspberry: GPIO - R 1K - LED - GND

Arduino: VCC - LDR - analog PIN

- R 10K - GND

Arduino väljund vt =AC 220V=

=AC 220V=

AC 220 sisendis enne toiteplokke:

AC 220V sulavkaitse 3A

* toiteplokk 12V 180W/220V/0,8=1,02A

* toiteplokk 24V 150W/220V/0,8=0,85A

* Sum 0,85+1,02=1,87/0,8=2,34A ~ 3A

toiteplokk AC->DC 5V

Arduino nano <- MQ2 andur

<- DS20B18 temperatuuriandur

<- Reset nupp

<- raspberry GPIO / Diy optocoupler

-> Buzzer

-> Red / Green LED

-> DC 5V- AC 220V relee (10A)

Pingestamisel:

* Väljundpinge 0V, Paus 30 sek (MQ2 stabiliseerimiseks) GreenLED ON, RedLED ON, Buzzer OFF

a. kui MQ2<150 ja temp<50 Väljund 220V, GreenLED ON, RedLED OFF, Buzzer OFF

b. Kui MQ2>150 või temp>50 Väljund 0V, GreenLED OFF, RedLED ON, Buzzer ON // kuni Reset nupu vajutuseni

* Reset Nupu kasutamisel uus kontroll ja vastav senaarium a. või b.

// 3D printer fire protect

// 13.06.2021

#include <OneWire.h>

#include <DallasTemperature.h>

#define ONE_WIRE_BUS 2 // digi pin 2

OneWire oneWire(ONE_WIRE_BUS);

DallasTemperature sensors(&oneWire);

int temp = 20;

int tempThres = 50;

int suits = 100;

int suitsThres = 150;

int ldrPin = A1; // raspberry input ldr

int ldrval=0;

int ldrThres = 300;

int redLed = 6;

int greenLed = 5;

int buzzer = 8;

int smokePin = A0;

int relay = 4;

bool f = false;

void setup() {

sensors.begin(); // Start up the library

pinMode(redLed, OUTPUT);

pinMode(greenLed, OUTPUT);

pinMode(buzzer, OUTPUT);

pinMode(smokePin, INPUT);

pinMode(ldrPin, INPUT);

pinMode(relay, OUTPUT);

Serial.begin(9600);

Serial.println("GO");

digitalWrite(redLed, HIGH);

digitalWrite(greenLed, HIGH);

digitalWrite(relay, HIGH);

delay(10000); // oota

while (f == false){

delay(1000);

mq2_go();

}

}

void mq2_go(){

suits = analogRead(smokePin);

delay(100);

if (suits > suitsThres)

{

f = false;

}

else

{

f = true;

}

}

void rpi() {

ldrval = analogRead(ldrPin);

delay(100);

//Serial.print("ldrPin: ");

//Serial.println(ldrval);

if (ldrval > ldrThres)

{

alarm();

}

else

{

ok();

}

}

void mq2x() {

suits = analogRead(smokePin);

delay(100);

//Serial.print("Pin A0: ");

//Serial.println(suits);

if (suits > suitsThres)

{

alarm();

}

else

{

ok();

}

}

void dallas() {

sensors.requestTemperatures();

delay(100);

temp = sensors.getTempCByIndex(0);

//Serial.print("Temperature: ");

//Serial.print(temp);

//Serial.println(" C");

if (temp > tempThres)

{

alarm();

}

else

{

ok();

}

}

void alarm() {

digitalWrite(redLed, HIGH);

digitalWrite(greenLed, LOW);

digitalWrite(relay, HIGH);

//Serial.println("Alarm");

buttonWait(9);

}

void ok() {

digitalWrite(redLed, LOW);

digitalWrite(greenLed, HIGH);

noTone(buzzer);

//Serial.print("OK");

digitalWrite(relay, LOW);

}

void buttonWait(int buttonPin){

int buttonState = 0;

while(1){

tone(buzzer, 1000);

buttonState = digitalRead(buttonPin);

if (buttonState == HIGH) {

return;

}

}

}

void loop() {

dallas();

delay(500);

mq2x();

delay(500);

rpi();

delay(500);

}Printeri Start Kood:

CURA seadistus:

Parameetrite loend: http://files.fieldofview.com/cura/Replacement_Patterns.html

Start G-code

START_PRINT T_BED={material_bed_temperature_layer_0} T_EXTRUDER={material_print_temperature_layer_0}End G-code

END_PRINT

Klipperi conf file printer.cfg

Kasutab ainult Cura temperatuure, muu juba Klipperi macrost:

Voodi-Nozzle asend redigeeri viimast rida: #*# z-offset = -0.3 (väiksemaks siis voodi nozzle vahe on väiksem; suuremaks siis vahe on suurem)

# This file contains common pin mappings for RAMPS (v1.3 and later)

# boards. RAMPS boards typically use a firmware compiled for the AVR

# atmega2560 (though other AVR chips are also possible).

# See docs/Config_Reference.md for a description of parameters.

[stepper_x]

step_pin: ar54

dir_pin: ar55

enable_pin: !ar38

microsteps: 64

rotation_distance: 40

endstop_pin: ^!ar3

#endstop_pin: ^ar2

position_endstop: 0

position_max: 200

homing_speed: 50

[tmc2209 stepper_x]

uart_pin: ar63

interpolate: True

run_current: 0.8

hold_current: 0.5

sense_resistor: 0.110

stealthchop_threshold: 60

[stepper_y]

step_pin: ar60

dir_pin: ar61

enable_pin: !ar56

microsteps: 64

rotation_distance: 40

endstop_pin: ^!ar14

#endstop_pin: ^ar15

position_endstop: 0

position_max: 200

homing_speed: 50

[tmc2209 stepper_y]

uart_pin: ar40

interpolate: True

run_current: 0.8

hold_current: 0.5

sense_resistor: 0.110

stealthchop_threshold: 60

[stepper_z]

step_pin: ar46

dir_pin: ar48

enable_pin: !ar62

microsteps: 64

rotation_distance: 8

endstop_pin: ^!ar18

#endstop_pin: ^ar19

position_endstop: 0

position_max: 191

#position_min: -1

[tmc2209 stepper_z]

uart_pin: ar42

interpolate: True

run_current: 0.90

hold_current: 0.5

sense_resistor: 0.110

stealthchop_threshold: 100

[probe]

pin: ^!ar19

x_offset: 5

y_offset: -45

#z_offset: 0.1

[bed_mesh]

speed: 150

horizontal_move_z: 5

mesh_min: 10,10

mesh_max: 190, 150

probe_count: 5,5

[extruder]

step_pin: ar26

dir_pin: ar28

enable_pin: !ar24

microsteps: 64

rotation_distance: 29.474

nozzle_diameter: 0.400

filament_diameter: 1.750

heater_pin: ar10

sensor_type: NTC 100K beta 3950

sensor_pin: analog13

#sensor_pin: ar67

control: pid

pid_Kp: 18.404

pid_Ki: 0.538

pid_Kd: 157.351

min_temp: 0

max_temp: 280

pressure_advance: 0.12

# pressure_advance: 0.15

[tmc2209 extruder]

uart_pin: ar44

interpolate: True

run_current: 0.7

hold_current: 0.4

sense_resistor: 0.110

stealthchop_threshold: 60

[heater_bed]

heater_pin: ar8

sensor_type: EPCOS 100K B57560G104F

sensor_pin: analog14

control = pid

pid_kp = 67.576

pid_ki = 0.994

pid_kd = 1147.945

min_temp: 0

max_temp: 130

[fan]

pin: ar7

[heater_fan my_nozzle_fan]

pin: ar9

heater: extruder

heater_temp: 50.0

fan_speed: 1.0

[mcu]

serial: /dev/serial/by-id/usb-FTDI_FT232R_USB_UART_A10JJR2O-if00-port0

pin_map: arduino

restart_method = command

[printer]

kinematics: cartesian

max_velocity: 300

max_accel: 3000

max_z_velocity: 10

max_z_accel: 50

square_corner_velocity: 1

[pause_resume]

recover_velocity: 50

###########################################################################

[gcode_macro M600]

default_parameter_X: 0

default_parameter_Y: 0

default_parameter_Z: 30

gcode:

SAVE_GCODE_STATE NAME=M600_state

PAUSE

G91

G1 E-.8 F2700

G1 Z{Z}

G90

#G1 X{X} Y{Y} F3000

G91

#G1 E-50 F1000

RESTORE_GCODE_STATE NAME=M600_state

#####################

[gcode_macro m205] ; hide M205 error

gcode:

#####################

[gcode_macro PREHEAT]

gcode:

M140 S70 ; start bed temp.

M190 S70 ; wait bed temp.

M104 S240 ; set nozzle temp.

M140 S80 ; start bed temp.

M109 S240 ; wait nozzle temp.

M190 S80 ; wait bed temp.

{% if printer.toolhead.homed_axes != "xyz" %}

G28

{% endif %}

G0 Z30 ; Z = 20 mm

######################

[gcode_macro POSITION]

gcode:

M114

######################

[gcode_macro CENTER_Z30]

gcode:

{% if printer.toolhead.homed_axes != "xyz" %}

G28

{% endif %}

G0 X100 Y100 Z30

[gcode_macro CENTER_Z0]

gcode:

{% if printer.toolhead.homed_axes != "xyz" %}

G28

{% endif %}

G0 X100 Y100 Z0

######################

[gcode_macro HOME]

gcode:

G28

[gcode_macro BED_CAL_AUTO]

gcode:

{% if printer.toolhead.homed_axes != "xyz" %}

G28

{% endif %}

BED_MESH_CALIBRATE METHOD=automatic

#####################################################

[gcode_macro START_PRINT T_BED T_EXTRUDER]

#variable_parameter_T_BED: 60

#variable_parameter_T_EXTRUDER: 190

gcode:

G90 ; set to absolute positioning - this line was added in case Cura doesn't include it by default

M82 ; set extruder to absolute mode - this line was added in case Cura doesn't include it by default (may not be needed)

G28 ; home all axe

# Move the nozzle near the bed

G1 X15 Y20 Z5 F6000

M117 Waiting for temperature

# Start bed heating and continue

M140 S{T_BED}

{% if printer.heater_bed.temperature < params.T_BED|float*0.84 %}

M190 S{params.T_BED|float*0.84} # wait till 0.85 of bed temp is reached, then continue

{% endif %}

M140 S{T_BED}

M109 S{T_EXTRUDER}

M190 S{T_BED}

; The lines below are to prep the nozzle before a print begins

G1 Z0.2 F1200 ; raise nozzle 0.2mm

G92 E0 ; reset extrusion distance

G1 Y1 ; move Y-Axis (bed) 1mm to prep for purge

G1 X100 E12 F600 ; move X-carriage 100mm while purging 12mm of filament

G92 E0 ; reset extrusion distance

G1 F200 E3

G92 E0

[gcode_macro END_PRINT]

gcode:

M104 S0

M140 S0

G92 E1

G1 E-1 F300

G28 X0 Y190

M84

[respond]

[pause_resume]

#####################################################

#https://klipper.discourse.group/t/macro-creation-tutorial/30/2

#######################################################

[gcode_macro scan_start]

gcode:

{% set x_s = 10 %} # set x startpoint

{% set y_s = 50 %} # set y startpoint

{% set z_s = 30 %} # set z startpoint

{% if printer.toolhead.homed_axes != "xyz" %}

G28

{% endif %}

G90 #absolut pos

G0 X{x_s} Y{y_s} Z{z_s}

M400

M118 INSERT OBJECT # Insert scanning object !

M118 Run macro SCAN_RUN # resume !

###############################################################

[gcode_macro scan_run]

gcode:

{% set scan_max = 21 %} # set scan lenght

{% set scan_step = 5 %} # set scan step lenght mm

{% set r = scan_max // scan_step %} # set scan steps

{% for x in range(0,r,1) %}

RUN_SHELL_COMMAND CMD=ledon

G91

G0 Y-{scan_step}

M400

G4 P2000

RUN_SHELL_COMMAND CMD=ledoff

M400

{% endfor %}

##############################################################

[gcode_shell_command ledon]

command: node /home/pi/scripts/ledon.js

#timeout: 5.

#verbose: True

[gcode_shell_command ledoff]

command: python /home/pi/scripts/ledoff.py

timeout: 2.

verbose: True

##############################################################

######################

[gcode_macro CENTER_lilscan]

gcode:

{% if printer.toolhead.homed_axes != "xyz" %}

G28

{% endif %}

G0 X32 Y80 Z140

################################################################

#*# <---------------------- SAVE_CONFIG ---------------------->

#*# DO NOT EDIT THIS BLOCK OR BELOW. The contents are auto-generated.

#*#

#*# [probe]

#*# z_offset = -0.35

#*#

#*# [bed_mesh default]

#*# version = 1

#*# points =

#*# 0.556875, 0.534375, 0.510625, 0.513750, 0.598750

#*# 0.450000, 0.455000, 0.451875, 0.453125, 0.463750

#*# 0.411875, 0.417500, 0.416875, 0.410625, 0.416875

#*# 0.403750, 0.413750, 0.414375, 0.404375, 0.401875

#*# 0.420625, 0.442500, 0.440000, 0.425000, 0.411875

#*# tension = 0.2

#*# min_x = 10.0

#*# algo = lagrange

#*# y_count = 5

#*# mesh_y_pps = 2

#*# min_y = 10.0

#*# x_count = 5

#*# max_y = 150.0

#*# mesh_x_pps = 2

#*# max_x = 190.0

RAMPS 1.4 pinmapping

// For RAMPS 1.4

#define X_STEP_PIN 54

#define X_DIR_PIN 55

#define X_ENABLE_PIN 38

#define X_MIN_PIN 3

#define X_MAX_PIN 2

#define Y_STEP_PIN 60

#define Y_DIR_PIN 61

#define Y_ENABLE_PIN 56

#define Y_MIN_PIN 14

#define Y_MAX_PIN 15

#define Z_STEP_PIN 46

#define Z_DIR_PIN 48

#define Z_ENABLE_PIN 62

#define Z_MIN_PIN 18

#define Z_MAX_PIN 19

#define E_STEP_PIN 26

#define E_DIR_PIN 28

#define E_ENABLE_PIN 24

#define SDPOWER -1

#define SDSS 53

#define LED_PIN 13

#define FAN_PIN 9

#define PS_ON_PIN 12

#define KILL_PIN -1

#define HEATER_0_PIN 10

#define HEATER_1_PIN 8

#define TEMP_0_PIN 13 // ANALOG NUMBERING

#define TEMP_1_PIN 14 // ANALOG NUMBERING

A0 A1 A2 A3 A4 A5 A6 A7 A8 A9 A10 A11 A12 A13 A14 A15

54 55 56 57 58 59 60 61 61 63 64 65 66 67 68 69

ET

ET  EN

EN